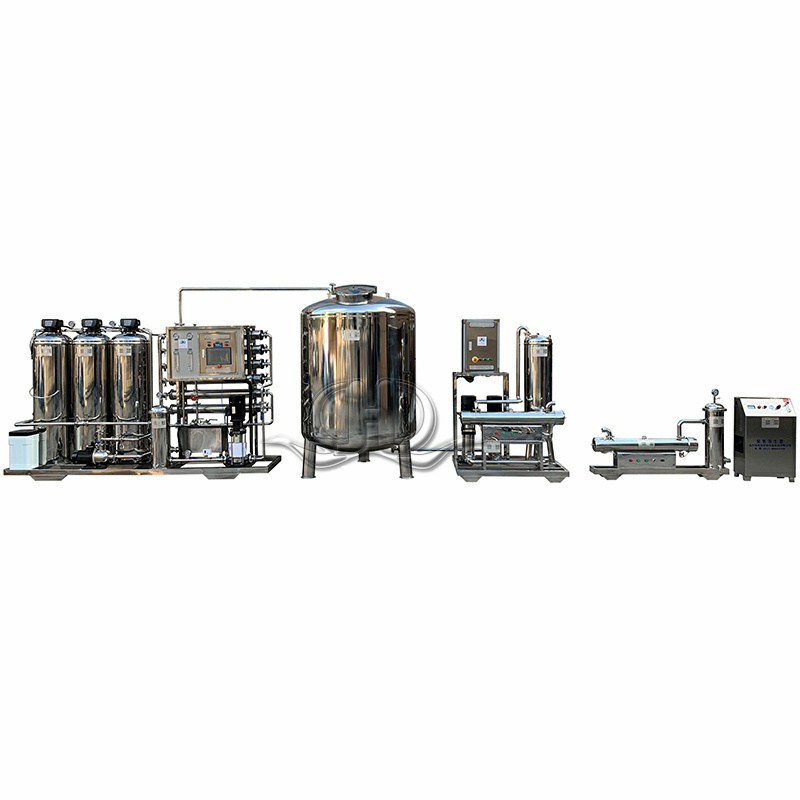

Auto Reverse Osmosis Filtration Equipment

Introduction and Maintenance Knowledge of Reverse Osmosis Pure Water Equipment

|

Product Detail |

|||||

|

1 |

Inlet water Type |

Well water/ underground water |

Outlet water Type |

Purified Water |

|

|

2 |

Inlet water TDS |

Below 2000ppm |

Desalination rate |

98%-99% |

|

|

3 |

Inlet Water Pressure |

0.2-04mpa |

Outlet water Usage |

Coating material production |

|

|

4 |

Inlet Membrane Water SDI |

≤5 |

Inlet Membrane Water COD |

≤3mg/L |

|

|

5 |

Inlet Water temperature |

2-45℃ |

Outlet capacity |

500-100000 litre per hour |

|

|

Technical Parameters |

|||||

|

1 |

Raw Water Pump |

0.75KW |

SS304 |

||

|

2 |

Pre-treatment part |

Runxin automatic valve/ stainless steel 304 Tank |

SS304 |

||

|

3 |

High pressure Pump |

2.2KW |

SS304 |

||

|

4 |

RO Membrane |

Membrane 0.0001micron pore size desalination rate 99%, recovery rate 50%-60%. |

Polyamide |

||

|

5 |

Electrical control system |

Air switch, electrical relay, alternating current contactor switch, control box |

|||

|

6 |

Frame and Pipe Line |

SS304 and DN25 |

|||

|

Function Parts |

|||||

|

NO |

Name |

Description |

Purifying Accuracy |

||

|

1 |

Quartz Sand Filter |

reducing turbidity, suspended matter, organic matter,colloid etc. |

100um |

||

|

2 |

Activated carbon filter |

remove the color,free chlorine, organic matter, harmful matter etc. |

100um |

||

|

3 |

Cation softener |

reducing water total hardness, make water soft and tasty |

100um |

||

|

4 |

Pp filter cartridge |

prevent large particles, bacteria,viruses into ro membranes, remove particles, colloids, organic impurities, heavy metal ions |

5 Micron |

||

|

5 |

Reverse osmosis membrane |

bacteria, virus, heat source etc. harmful substance and 99% dissolved salts. |

0.0001um |

||

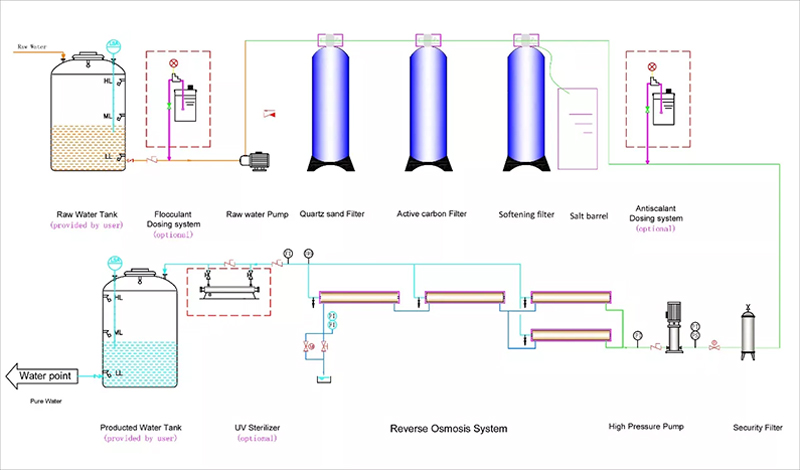

Processing: Feed water Tank→feed water pump→quartz sand filter→active carbon filter→softener→security filter→High pressure Pump→reverse osmosis system→pure water Tank

Currently, the process used to produce pure water in the market mostly uses reverse osmosis desalination and purification technology. Reverse osmosis pure water equipment has advantages such as stable water production, high intelligence, low operating cost, and small floor area. Below is an introduction and maintenance knowledge of reverse osmosis pure water equipment, hoping to provide valuable reference for everyone.

1. The typical pre-treatment unit of reverse osmosis pure water equipment includes pre-treatment filtration to remove large particles, adding oxidants such as sodium hypochlorite, then precision filtration through a multi-media filter or a clarifier, adding a reducing agent such as sodium hydrogen sulfite to reduce residual chlorine and other oxidants, and using precision filtration before the high-pressure pump inlet.

If the water source contains more suspended particles, more sophisticated pre-treatment filtration interception is needed to meet the specified inlet requirements. For water sources with high hardness content, softening, acidification, and anti-scaling agents are recommended. For water sources with high microbial and organic matter content, activated carbon or anti-pollution membrane elements are also required.

2. What kind of raw water source should use reverse osmosis technology or ion exchange technology?

Under many inlet conditions, ion exchange resins or reverse osmosis can be used. The choice of technology should be determined by economic comparison. Generally, the higher the salt content, the more economical the reverse osmosis technology is. The lower the salt content, the more economical the ion exchange technology is. Due to the widespread use of reverse osmosis technology, the combination of reverse osmosis + ion exchange technology, multi-stage reverse osmosis, or reverse osmosis + other deep desalination technologies has become a recognized technical and economically reasonable water treatment solution.

3. How often should the reverse osmosis pure water equipment system be cleaned?

Under normal circumstances, when the standardized flux drops by 10-15%, or the system desalination rate drops by 10-15%, or the operation pressure and inter-stage pressure difference increases by 10-15%, the RO system should be cleaned. The cleaning frequency is directly related to the system pre-treatment level. When SDI15 is less than 3, the cleaning frequency may be four times a year; when SDI15 is about 5, the cleaning frequency may need to be doubled.

4. How long can the RO membrane system stop without flushing?

If the system uses an anti-scaling agent, when the water temperature is around 25°C, it can stop for about four hours; when the temperature is below 20°C, it can stop for about eight hours. If the system is not using an anti-scaling agent, it can stop for about one day.

5. How long can reverse osmosis (RO) membrane elements be used?

The service life of a reverse osmosis membrane depends on the chemical stability, physical stability, cleanability, raw water source, pre-treatment, cleaning frequency, and operational management level of the membrane element.