Big Capacity Deionized Two Stage Reverse Osmosis Water Treatment Machinery

| NO. | Description | Data | |

| 1 | Salt rejection rate | 98.5% | |

| 2 | Working pressure | 0.6-2.0Mpa | |

| 3 | Voltage | 200v/50Hz,380V/50Hz etc. customized | |

| 4 | Material | Ss,CPVC,FRP,PVC | |

| 5 | Raw water (sea water) | TDS | <35000PPM |

| Temperature | 15℃-45℃ | ||

| Recovery Rate | 55℃ | ||

| 6 | Water-out conductivity(us/cm) | 3-8 | |

| 7 | Reverse Osmosis (RO) membrane | 8040/4040 | |

| 8 | Inlet Water SDI | <5 | |

| 9 | Inlet Water PH | 3-10 | |

|

Product characteristic |

|||||||

| Item | Capacity(T/H) | Power(KW) | Recovery(%) | One stage water conductivity(μs/cm) | Two Stage water conductivity (μs/cm) | EDI Water conductivity (μs/cm) | Raw water conductivity (μs/cm) |

| HDN-500 | 0.5 | 0.85 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-1000 | 1.0 | 2.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-2000 | 2.0 | 2.2 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-3000 | 3.0 | 3.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-5000 | 5.0 | 5.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-6000 | 6.0 | 6.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-10000 | 10.0 | 10.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-20000 | 20.0 | 20.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| Components and functions | ||

| NO. | Name | Application |

| 1 | Raw water Tank | Store water,buffering pressure,overcome instability of supplying water by pipe,Ensure to supply water stable and continuously for whole system,normally customer provided |

| 2 | Raw water Pump | Provide needed pressure for every pretreatment filter |

| 3 | Mechanical filter | We use fiber glass or stainless steel vessel as housing, fill quartz sand,it can filter big particles impurities, Suspended substances, colloids etc. |

| 4 |

Activated carbon filter |

We use fiber glass or stainless steel vessel as Housing, fill activated carbon, remove color, odor, residual chlorine and organics substances. |

| 5 | Water softener | Adopt cation resin to soften water, cation resin will absorb Ca2+, Mg2+(Main elements for composing scale) |

| 6 | Security filter or pp filter | Prevent large particles, bacteria,viruses into RO membrane, Accuracy is 5 μs |

| 7 | High Pressure Pump | adopt two stage high pressure pump. Provide needed working pressure for RO system,High pressure pump ensure production capacity of pure water.(CNP pump or custom other brand) |

| 8 | Reverse osmosis System | Adopt two stage reverse osmosis system.Can remove particles colloids,organicRO(reverse osmosis)system impurities,heavy metal ions,bacteria,virus,heat source etc.harmful substances and 99% dissolved salts.(RO membranes USA Film tec); Output water conductivity≤2us/cm. |

Characteristics of Water Purification Equipment:

1. The entire system is configured with stainless steel, which runs stable and has a refined and beautiful appearance.

2. Equipped with a raw water tank and an intermediate water tank to prevent the impact of unstable tap water pressure on the equipment.

3. Equipped with a dedicated purified water tank with a digital electronic level gauge, rotating spray cleaning, and empty ventilation device.

4. Adopting imported Dow Chemical reverse osmosis membrane BW ultra-low pressure membrane, with high desalination rate, stable operation, and 20% energy consumption reduction.

5. Equipped with a pH adjustment and online detection system to regulate the pH value and prevent the influence of CO2 on the water quality of the produced water.

6. Equipped with ozone and ultraviolet sterilization systems and terminal microfiltration devices.

7. The control system adopts a fully automatic method, with main components using imported components, high stability, and easy and convenient operation.

8. Equipped with a purified water delivery and supply system.

9. All key materials use internationally renowned brands in the industry to ensure quality and are designed with the best configuration.

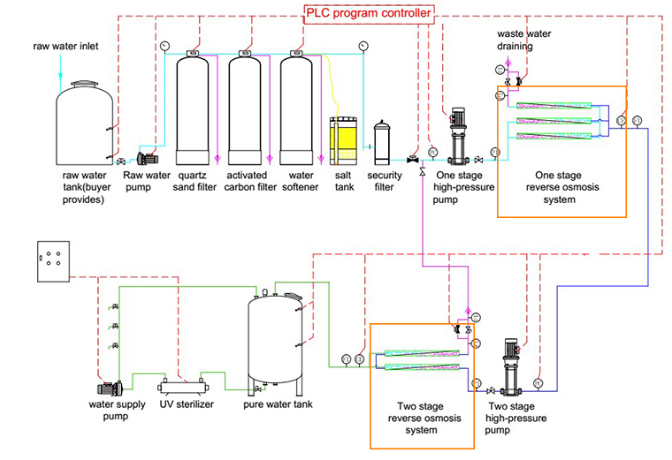

WZHDN Purified Water Equipment Process Flow:

Raw Water → Raw Water Tank → Raw Water Pump → Multi-Media Filter → Activated Carbon Filter → Water Softener → Safety Filter → First-Level RO System → First-Level RO Water Tank (with pH adjustment device) → Second-Level RO System → Second-Level Purified Water Tank → Purified Water Pump (with ozone sterilization system) → Ultraviolet Sterilization → 0.22μm Microfiltration → Purified Water Use Point

How to maintain purified water equipment on a daily basis?

Purified water equipment generally uses reverse osmosis treatment technology to remove impurities, salts, and heat sources from water bodies, and is widely used in industries such as medicine, hospitals, and biochemical chemical industry.

The core technology of purified water equipment uses new processes such as reverse osmosis and EDI to design a complete set of purified water treatment processes with targeted features. So, how should purified water equipment be maintained and maintained on a daily basis? The following tips may be helpful:

Sand filters and carbon filters should be cleaned at least every 2-3 days. Clean the sand filter first and then the carbon filter. Perform backwash, before forward washing. Quartz sand consumables should be replaced after 3 years, and activated carbon consumables should be replaced after 18 months.

The precision filter only needs to be drained once a week. The PP filter element inside the precision filter should be cleaned once a month. The filter can be disassembled and removed from the shell, rinsed with water, and then reassembled. It is recommended to replace it after about 3 months.

The quartz sand or activated carbon inside the sand filter or carbon filter should be cleaned and replaced every 12 months.

If the equipment is not used for a long time, it is recommended to run at least 2 hours every 2 days. If the equipment is shut down at night, the quartz sand filter and activated carbon filter can be backwashed using tap water as the raw water.

If the gradual reduction of water production by 15% or the gradual decline in water quality exceeds the standard is not caused by temperature and pressure, it means that the reverse osmosis membrane needs to be chemically cleaned.

During operation, various malfunctions may occur due to various reasons. After a problem occurs, check the operation record in detail and analyze the cause of the fault.

Features of purified water equipment:

Simple, reliable, and easy-to-install structure design.

The entire purified water treatment equipment is made of high-quality stainless steel material, which is smooth, without dead angles, and easy to clean. It is resistant to corrosion and rust prevention.

Directly using tap water to produce sterile purified water can completely replace distilled water and double-distilled water.

The core components (reverse osmosis membrane, EDI module, etc.) are imported.

The full automatic operation system (PLC + human-machine interface) can perform efficient automatic washing.

Imported instruments can accurately, continuously analyze, and display water quality.