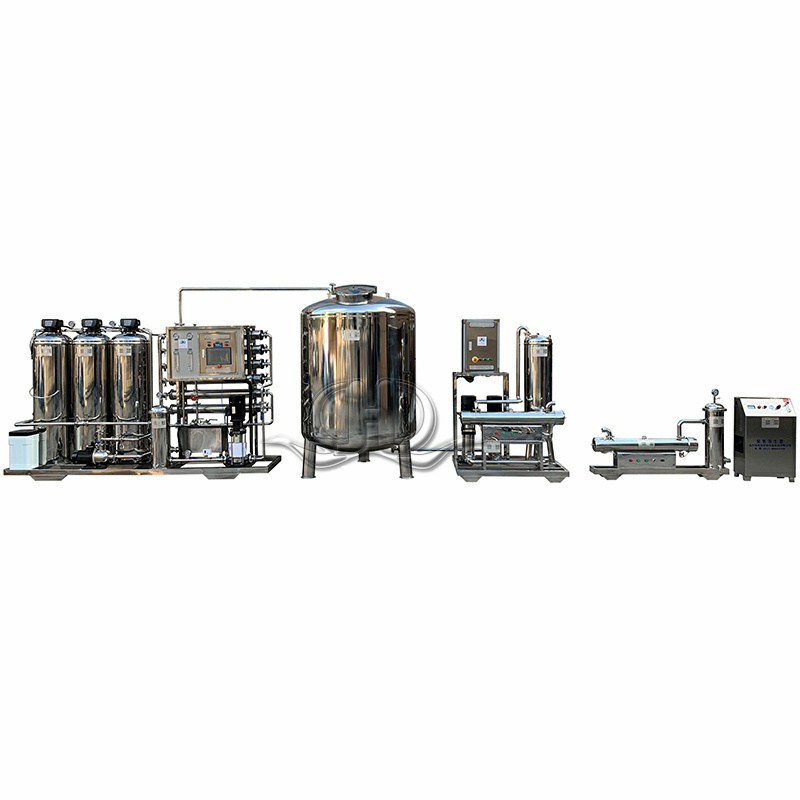

borehole water purifier machine ro water filter

Introduction and Maintenance Knowledge of Reverse Osmosis Pure Water Equipment

|

Product Detail |

|||||

|

1 |

Inlet water Type |

Well water/ underground water |

Outlet water Type |

Purified Water |

|

|

2 |

Inlet water TDS |

Below 2000ppm |

Desalination rate |

98%-99% |

|

|

3 |

Inlet Water Pressure |

0.2-04mpa |

Outlet water Usage |

Coating material production |

|

|

4 |

Inlet Membrane Water SDI |

≤5 |

Inlet Membrane Water COD |

≤3mg/L |

|

|

5 |

Inlet Water temperature |

2-45℃ |

Outlet capacity |

500-100000 litre per hour |

|

|

Technical Parameters |

|||||

|

1 |

Raw Water Pump |

0.75KW |

SS304 |

||

|

2 |

Pre-treatment part |

Runxin automatic valve/ stainless steel 304 Tank |

SS304 |

||

|

3 |

High pressure Pump |

2.2KW |

SS304 |

||

|

4 |

RO Membrane |

Membrane 0.0001micron pore size desalination rate 99%, recovery rate 50%-60% |

Polyamide |

||

|

5 |

Electrical control system |

Air switch, electrical relay, alternating current contactor switch, control box |

|||

|

6 |

Frame and Pipe Line |

SS304 and DN25 |

|||

|

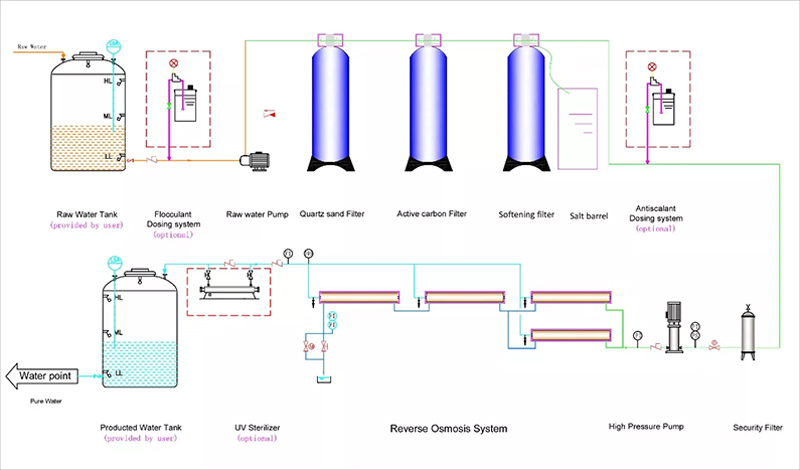

Function Parts |

|||||

|

NO |

Name |

Description |

Purifying Accuracy |

||

|

1 |

Quartz Sand Filter |

reducing turbidity, suspended matter, organic matter, colloid etc. |

100um |

||

|

2 |

Activated carbon filter |

remove the color, free chlorine, organic matter, harmful matter etc. |

100um |

||

|

3 |

Cation softener |

reducing water total hardness, make water soft and tasty |

100um |

||

|

4 |

Pp filter cartridge |

prevent large particles, bacteria, viruses into ro membranes, remove particles, colloids, organic impurities, heavy metal ions |

5 Micron |

||

|

5 |

Reverse osmosis membrane |

bacteria, virus, heat source etc. harmful substance and 99% dissolved salts. |

0.0001um |

||

Processing: Feed water Tank→feed water pump→quartz sand filter→active carbon filter→softener→security filter→High pressure Pump→reverse osmosis system→pure water Tank

How to decrease the hardness of water?

Whether pretreatment of reverse osmosis equipment requires softening depends on the hardness level of the water and the requirements for reverse osmosis. If the water hardness is high and reverse osmosis requires higher purity water, then softening pretreatment is usually necessary.

The main purpose of softening pretreatment is to remove calcium and magnesium ions in the water and reduce the hardness of the water to protect the reverse osmosis membrane from scale and improve the efficiency and life of the reverse osmosis equipment. For water with high hardness, softening pretreatment can reduce fouling and sealing on the membrane surface, thereby reducing membrane resistance and improving reverse osmosis performance.

If softening pretreatment is not performed, the hardness in the water can also be removed by other means, such as using anion exchange resin, decalcification and demagnesization by adding chemicals such as oxalic acid, or using nanofilters to remove dissolved solids in the water.

Antiscalants can be added to reverse osmosis water treatment equipment to prevent the formation of scale. Scale is a solid substance formed by the hardness components in the water deposited on the surface of the reverse osmosis membrane. It will reduce the efficiency and life of the reverse osmosis equipment.

Antiscalants are special chemicals that react with hardness components in water to prevent scale from forming. Antiscalants can work in two ways:

Dispersion: Antiscalants can disperse hardness components in water and prevent them from depositing on the surface of the reverse osmosis membrane. This reduces the risk of scale and maintains efficient operation of the reverse osmosis equipment.

Chelation: Antiscalants can chemically react with hardness components in water to form chelates with higher solubility. These chelates can exist stably in water and avoid the formation of scale.

It is important to note that selecting the appropriate antiscalant depends on the water hardness level and the requirements of the reverse osmosis equipment. Different water qualities and equipment may require different antiscalant formulations.