Drinking water filtration system and ozone generator

Introduction and Maintenance Knowledge of Reverse Osmosis Pure Water Equipment

|

Product Detail |

|||||

|

1 |

Inlet water Type |

Well water/ underground water |

Outlet water Type |

Purified Water |

|

|

2 |

Inlet water TDS |

Below 2000ppm |

Desalination rate |

98%-99% |

|

|

3 |

Inlet Water Pressure |

0.2-04mpa |

Outlet water Usage |

Coating material production |

|

|

4 |

Inlet Membrane Water SDI |

≤5 |

Inlet Membrane Water COD |

≤3mg/L |

|

|

5 |

Inlet Water temperature |

2-45℃ |

Outlet capacity |

2000 litre per hour |

|

|

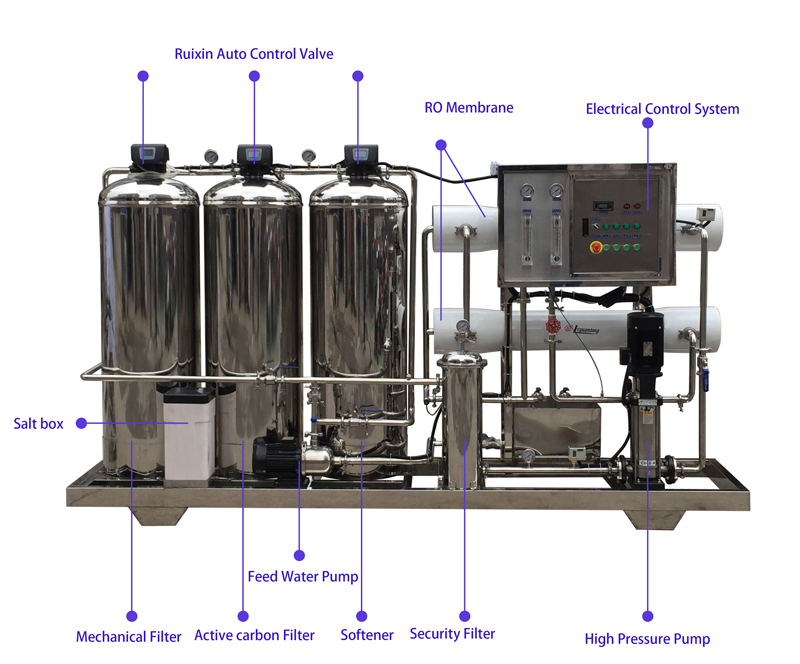

Technical Parameters |

|||||

|

1 |

Raw Water Pump |

0.75KW |

SS304 |

||

|

2 |

Pre-treatment part |

Runxin automatic valve/ stainless steel 304 Tank |

SS304 |

||

|

3 |

High pressure Pump |

2.2KW |

SS304 |

||

|

4 |

RO Membrane |

Membrane 0.0001micron pore size desalination rate 99%, recovery rate 50%-60% |

Polyamide |

||

|

5 |

Electrical control system |

Air switch, electrical relay, alternating current contactor switch, control box |

|||

|

6 |

Frame and Pipe Line |

SS304 and DN25 |

|||

|

Function Parts |

|||||

|

NO |

Name |

Description |

Purifying Accuracy |

||

|

1 |

Quartz Sand Filter |

reducing turbidity, suspended matter, organic matter, colloid etc. |

100um |

||

|

2 |

Activated carbon filter |

remove the color, free chlorine, organic matter, harmful matter etc. |

100um |

||

|

3 |

Cation softener |

reducing water total hardness, make water soft and tasty |

100um |

||

|

4 |

Pp filter cartridge |

prevent large particles, bacteria, viruses into ro membranes, remove particles, colloids, organic impurities, heavy metal ions |

5 Micron |

||

|

5 |

Reverse osmosis membrane |

bacteria, virus, heat source etc. harmful substance and 99% dissolved salts. |

0.0001um |

||

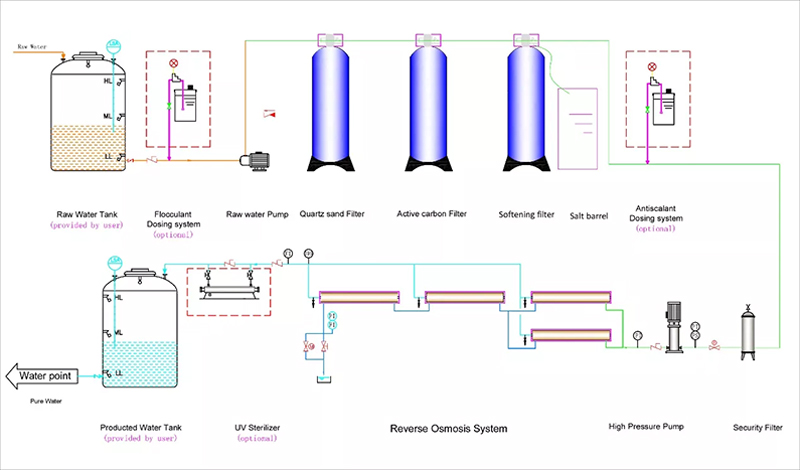

Processing: Feed water Tank→feed water pump→quartz sand filter→active carbon filter→softener→security filter→High pressure Pump→reverse osmosis system→pure water Tank

An ozone mixing tower is a device used to mix ozone with other gases or liquids. It usually consists of a feed tube, a nozzle or atomizer and a mixing area. After the ozone enters the mixing tower, it is dispersed into small particles or bubbles through a nozzle or atomizer, and is fully mixed with the feed gas or liquid.

The main function of the ozone mixing tower is to fully mix ozone with other gases or liquids to improve the utilization and effect of ozone. The mixed ozone can be used in different fields, such as oxidation, disinfection and deodorization in water treatment and air purification.

Unlike ozone sterilizers, ozone mixing towers are mainly used to mix ozone with other gases or liquids, rather than being directly used for sterilization and disinfection. It plays an important role in some industrial and environmental applications, helping to enhance chemical reactions and improve gas or liquid quality.

An ozone mixing tower is a device used to mix oxygen and ozone. Ozone is a gas with strong oxidizing effect and is widely used in fields such as water treatment, air purification and disinfection.

Ozone mixing towers usually consist of one or more columns with mixers and distributors installed inside. Oxygen and ozone enter the mixing tower through the corresponding gas supply system. After being mixed evenly by the mixer, they are evenly distributed into the medium to be treated through the distributor.

Advantages of ozone mixing towers include:

Efficient oxidation: Ozone has a strong oxidation effect and can effectively remove pollutants such as organic matter, odor and color.

Fast reaction: Ozone reacts quickly with pollutants and has high treatment efficiency.

Adjustability: The ozone mixing tower can adjust the ozone concentration and flow rate according to treatment needs to obtain the best treatment effect.

No chemical residues: Ozone quickly decomposes into oxygen in water without producing harmful chemical residues.

Widely used: Ozone mixing towers are widely used in water treatment, wastewater treatment, air purification, food processing and medical and health fields.

Ozone sterilizer is a device that uses ozone gas for sterilization and disinfection. Ozone has highly oxidizing and bactericidal properties and can quickly and effectively kill bacteria, viruses, fungi and other microorganisms in the air and water.

Ozone sterilizers usually consist of an ozone generator, an ozone reaction chamber and a control system. The ozone generator generates ozone gas through ionization or induced discharge and introduces it into the ozone reaction chamber. After the air or water in the reaction chamber is treated with ozone gas, microorganisms such as bacteria and viruses can be quickly destroyed and eliminated.

The advantages of ozone sterilizers include:

Fast and efficient: Ozone has powerful sterilization and oxidation effects, and can quickly inactivate microorganisms in a short time.

Broad-spectrum sterilization: Ozone has a killing effect on bacteria, viruses, fungi and other microorganisms, and can comprehensively remove microbial pollution in the air and water.

No chemical residue: Ozone quickly decomposes into oxygen during the sterilization process and does not produce harmful chemical residues.

Odorless and tasteless: Ozone does not produce odor or smell during the sterilization process and will not affect the environment and indoor air quality.

Ozone sterilizers are widely used in medical and health places, laboratories, food industry, water treatment and air purification and other fields. When using an ozone sterilizer, correct operation and control must be carried out according to specific needs and application scenarios to ensure safe and efficient sterilization and disinfection. At the same time, it should also be noted that ozone has certain toxicity and danger. Operators should receive professional training and strictly abide by operating procedures and safety measures.