Reverse osmosis water has diverse applications and functions in the electronics and electrical industry, specifically in the production of microbattery products, computer circuit boards, semiconductors,chip sand batteries. Below, I will provide a detailed description regarding its uses and significance in these respective areas:

Microbattery products: Reverse osmosis water is crucial in the manufacturing process of microbatteries. It is employed in the electrode fabrication process where it ensures the purity of the materials used. Any impurities in water can lead to chemical reactions or degradation of the battery components, affecting its overall performance and lifespan. By utilizing reverse osmosis water, manufacturers can maintain the high-quality standards required for reliable and efficient microbattery production.

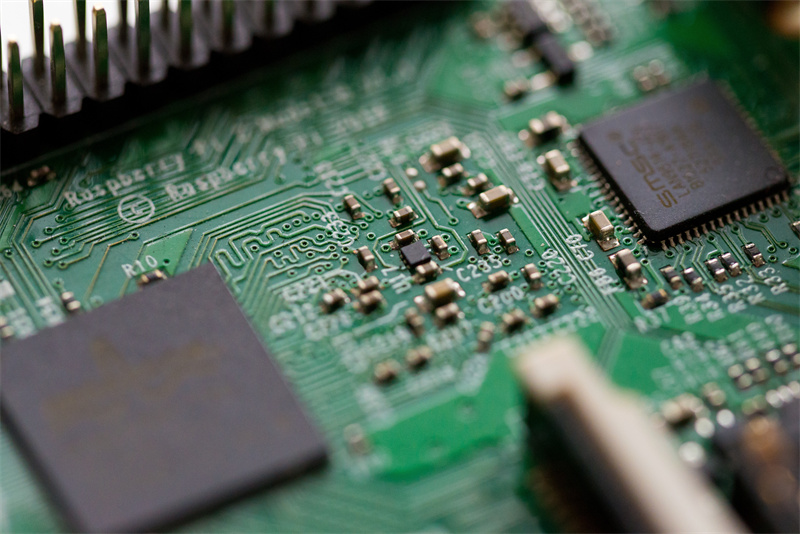

Computer circuit boards: Reverse osmosis water plays a key role in the production of computer circuit boards. It is employed in the cleaning and rinsing processes during circuit board manufacturing. The purity of reverse osmosis water helps eliminate any contamination or impurities that may adversely impact the functionality of the electronic components. It ensures the removal of dust, debris, and other particles that could hinder the proper functioning of the circuit board.

Chip fabrication: In chip fabrication, reverse osmosis water is used for wafer cleaning and etching. As the demands for smaller and more advanced chips increase, maintaining the purity of the cleaning agents becomes crucial. Reverse osmosis water's low mineral content and absence of impurities make it ideal for such processes.

Photolithography: Reverse osmosis water is extensively utilized in the photolithography process, which involves transferring circuit patterns onto semiconductor wafers. It is used for developing and rinsing the photoresist, a light-sensitive material used for creating the circuit patterns. The high purity of reverse osmosis water ensures precise and consistent patterning.

Photolithography: Reverse osmosis water is extensively utilized in the photolithography process, which involves transferring circuit patterns onto semiconductor wafers. It is used for developing and rinsing the photoresist, a light-sensitive material used for creating the circuit patterns. The high purity of reverse osmosis water ensures precise and consistent patterning.

Chemical mixing and formulation: Reverse osmosis water serves as a base for the preparation of various chemicals and solutions used in the electronics industry. It provides a clean and reliable solvent that can be precisely mixed with other chemicals to produce etchants, cleaning agents, and specialty solutions required in the manufacturing processes.

Ion implantation: Reverse osmosis water is used as a medium for ion implantation in the fabrication of semiconductor devices. It acts as a carrier for ions that are implanted into the substrate, contributing to the creation of specific regions with desired electrical properties.

Heat dissipation and cooling: In electronic devices such as computers, reverse osmosis water is employed in cooling systems. Its high purity and low mineral content prevent the formation of scale and deposits, ensuring efficient heat transfer and maintaining optimal operating temperatures.ts.

In summary, reverse osmosis water is highly valuable in the electronics and electrical industry, specifically in the production of microbattery products, computer circuit boards, and batteries. It ensures the purity of materials, eliminates contaminants, and supports the production of high-quality electronic components. Its use in cleaning, rinsing, and chemical formulation processes contributes to the efficiency, reliability, and overall performance of electronic devices and components.