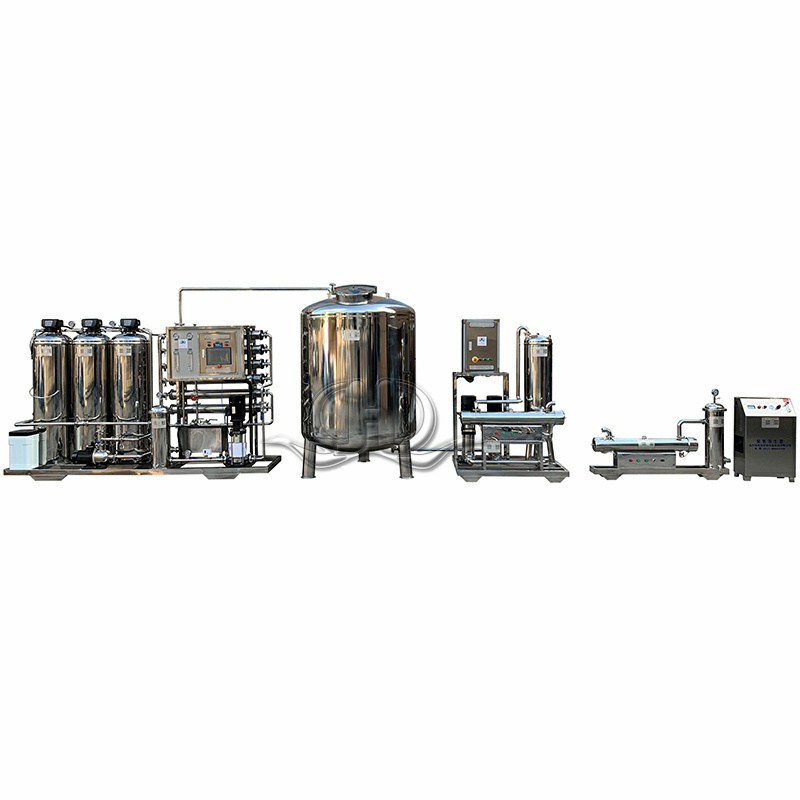

pretreatment ro water auto system treatment unit filter

Introduction and Maintenance Knowledge of Reverse Osmosis Pure Water Equipment

|

Product Detail |

|||||

|

1 |

Inlet water Type |

Well water/ underground water |

Outlet water Type |

Purified Water |

|

|

2 |

Inlet water TDS |

Below 2000ppm |

Desalination rate |

98%-99% |

|

|

3 |

Inlet Water Pressure |

0.2-04mpa |

Outlet water Usage |

Coating material production |

|

|

4 |

Inlet Membrane Water SDI |

≤5 |

Inlet Membrane Water COD |

≤3mg/L |

|

|

5 |

Inlet Water temperature |

2-45℃ |

Outlet capacity |

2000 litre per hour |

|

|

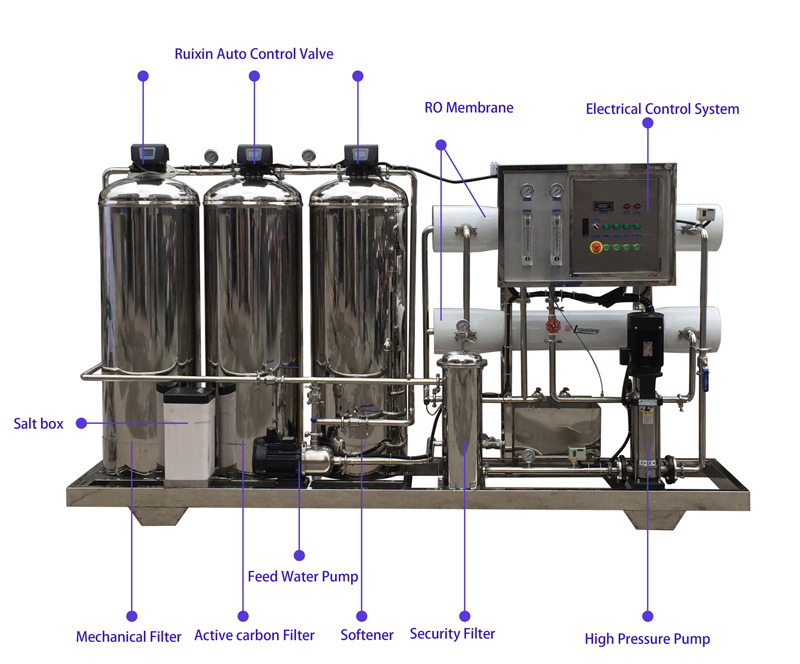

Technical Parameters |

|||||

|

1 |

Raw Water Pump |

0.75KW |

SS304 |

||

|

2 |

Pre-treatment part |

Runxin automatic valve/ stainless steel 304 Tank |

SS304 |

||

|

3 |

High pressure Pump |

2.2KW |

SS304 |

||

|

4 |

RO Membrane |

Membrane 0.0001micron pore size desalination rate 99%, recovery rate 50%-60% |

Polyamide |

||

|

5 |

Electrical control system |

Air switch, electrical relay, alternating current contactor switch, control box |

|||

|

6 |

Frame and Pipe Line |

SS304 and DN25 |

|||

|

Function Parts |

|||||

|

NO |

Name |

Description |

Purifying Accuracy |

||

|

1 |

Quartz Sand Filter |

reducing turbidity, suspended matter, organic matter, colloid etc. |

100um |

||

|

2 |

Activated carbon filter |

remove the color, free chlorine, organic matter, harmful matter etc. |

100um |

||

|

3 |

Cation softener |

reducing water total hardness, make water soft and tasty |

100um |

||

|

4 |

Pp filter cartridge |

prevent large particles, bacteria, viruses into ro membranes, remove particles, colloids, organic impurities, heavy metal ions |

5 Micron |

||

|

5 |

Reverse osmosis membrane |

bacteria, virus, heat source etc. harmful substance and 99% dissolved salts. |

0.0001um |

||

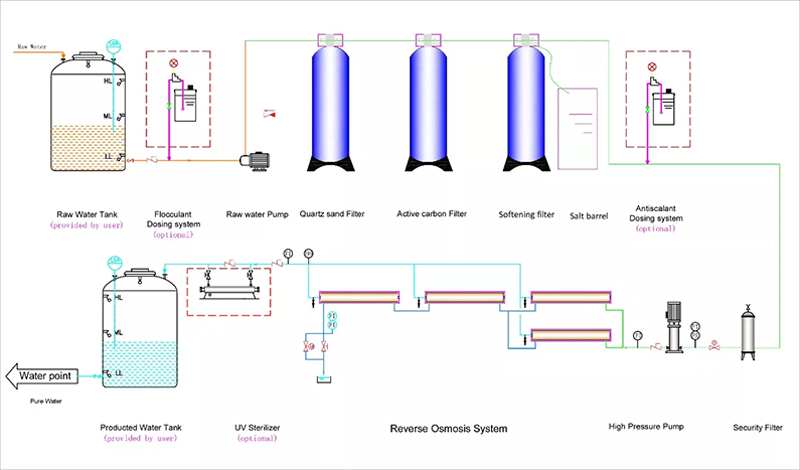

Processing: Feed water Tank→feed water pump→quartz sand filter→active carbon filter→softener→security filter→High pressure Pump→reverse osmosis system→pure water Tank

The difference between a pure water tank and a sterile water tank is the purity of the water and the presence or absence of microorganisms.

Pure water tanks are mainly used in general laboratories, industrial processing, electronic manufacturing, glass cleaning and other fields. It can obtain high-purity water by removing or reducing dissolved solids, dissolved gases, organic matter, bacteria and viruses in water. The water in pure water tanks is usually obtained after deionization, reverse osmosis and other processes. Although water can be purified to a high degree of purity, microorganisms can still be present in it.

Sterile water tanks are specially used in fields that require a high degree of sterility, such as medical treatment, laboratories, biopharmaceuticals, etc. Sterile water tanks must not only remove dissolved solids, dissolved gases, organic substances, etc. in the water, but also completely remove microorganisms in the water through filtration or other sterile treatment methods to ensure the sterility of the water quality. Normally, sterile water tanks focus on eliminating bacteria and viruses to ensure the sterility of the water.

Therefore, pure water tanks mainly focus on the purity of water quality, while sterile water tanks focus on the sterility of water quality. The specific type of water tank to be used should be selected based on actual needs and requirements.

FRP Membrane Housing refers to a membrane housing made from Fiberglass Reinforced Polymer (FRP) material. FRP is known for its high strength, durability, and corrosion resistance, making it suitable for various industrial and commercial applications. FRP membrane housings are commonly used in water treatment systems, particularly for reverse osmosis (RO) or ultrafiltration (UF) membranes.

Stainless steel Membrane Housing, on the other hand, as the name suggests, is a membrane housing made from stainless steel material. Stainless steel is widely recognized for its excellent corrosion resistance, mechanical strength, and hygienic properties. Stainless steel membrane housings are frequently used in industries such as food and beverage, pharmaceuticals, and medical applications where cleanliness and sanitary standards are paramount.

Both FRP and stainless steel membrane housings provide a secure enclosure for membranes used in water filtration systems. However, the choice between the two depends on the specific requirements of the application. Factors such as the nature of the water being treated, the operating conditions (e.g., temperature and pressure), and the desired lifespan of the membrane housing can influence the selection between FRP and stainless steel.