Reverse Osmosis Water Treatment Water Filter Machine For Pharmaceutical

| NO. | Description | Data | |

| 1 | Salt rejection rate | 98.5% | |

| 2 | Working pressure | 0.6-2.0Mpa | |

| 3 | Voltage | 200v/50Hz,380V/50Hz etc. customized | |

| 4 | Material | Ss,CPVC,FRP,PVC | |

| 5 | Raw water (sea water) | TDS | <35000PPM |

| Temperature | 15℃-45℃ | ||

| Recovery Rate | 55℃ | ||

| 6 | Water-out conductivity(us/cm) | 3-8 | |

| 7 | Reverse Osmosis (RO) membrane | 8040/4040 | |

| 8 | Inlet Water SDI | <5 | |

| 9 | Inlet Water PH | 3-10 | |

|

Product characteristic |

|||||||

| Item | Capacity(T/H) | Power(KW) | Recovery(%) | One stage water conductivity(μs/cm) | Two Stage water conductivity (μs/cm) | EDI Water conductivity (μs/cm) | Raw water conductivity (μs/cm) |

| HDN-500 | 0.5 | 0.85 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-1000 | 1.0 | 2.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-2000 | 2.0 | 2.2 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-3000 | 3.0 | 3.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-5000 | 5.0 | 5.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-6000 | 6.0 | 6.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-10000 | 10.0 | 10.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-20000 | 20.0 | 20.0 | 55-75 | <10 | <5 | <0.5 | <300 |

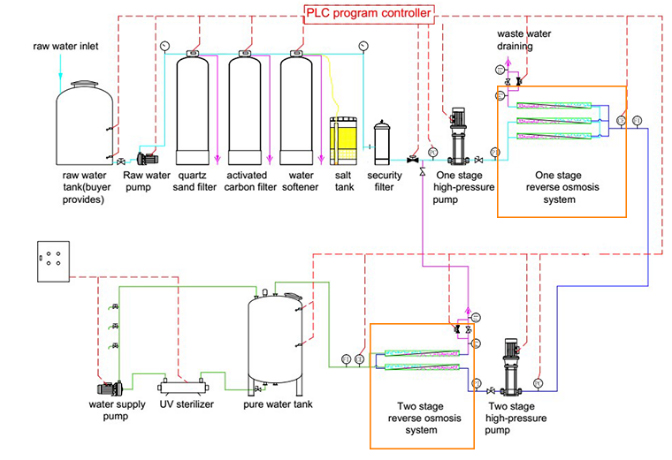

| Components and functions | ||

| NO. | Name | Application |

| 1 | Raw water Tank | Store water,buffering pressure,overcome instability of supplying water by pipe,Ensure to supply water stable and continuously for whole system,normally customer provided |

| 2 | Raw water Pump | Provide needed pressure for every pretreatment filter |

| 3 | Mechanical filter | We use fiber glass or stainless steel vessel as housing, fill quartz sand,it can filter big particles impurities, Suspended substances, colloids etc. |

| 4 |

Activated carbon filter |

We use fiber glass or stainless steel vessel as Housing, fill activated carbon, remove color, odor, residual chlorine and organics substances. |

| 5 | Water softener | Adopt cation resin to soften water, cation resin will absorb Ca2+, Mg2+(Main elements for composing scale) |

| 6 | Security filter or pp filter | Prevent large particles, bacteria,viruses into RO membrane, Accuracy is 5 μs |

| 7 | High Pressure Pump | adopt two stage high pressure pump. Provide needed working pressure for RO system,High pressure pump ensure production capacity of pure water.(CNP pump or custom other brand) |

| 8 | Reverse osmosis System | Adopt two stage reverse osmosis system.Can remove particles colloids,organicRO(reverse osmosis)system impurities,heavy metal ions,bacteria,virus,heat source etc.harmful substances and 99% dissolved salts.(RO membranes USA Film tec); Output water conductivity≤2us/cm. |

Characteristics of Water Purification Equipment:

1. The entire system is configured with stainless steel, which runs stable and has a refined and beautiful appearance.

2. Equipped with a raw water tank and an intermediate water tank to prevent the impact of unstable tap water pressure on the equipment.

3. Equipped with a dedicated purified water tank with a digital electronic level gauge, rotating spray cleaning, and empty ventilation device.

4. Adopting imported Dow Chemical reverse osmosis membrane BW ultra-low pressure membrane, with high desalination rate, stable operation, and 20% energy consumption reduction.

5. Equipped with a pH adjustment and online detection system to regulate the pH value and prevent the influence of CO2 on the water quality of the produced water.

6. Equipped with ozone and ultraviolet sterilization systems and terminal microfiltration devices.

7. The control system adopts a fully automatic method, with main components using imported components, high stability, and easy and convenient operation.

8. Equipped with a purified water delivery and supply system.

9. All key materials use internationally renowned brands in the industry to ensure quality and are designed with the best configuration.

WZHDN Purified Water Equipment Process Flow:

Raw Water → Raw Water Tank → Raw Water Pump → Multi-Media Filter → Activated Carbon Filter → Water Softener → Safety Filter → First-Level RO System → First-Level RO Water Tank (with pH adjustment device) → Second-Level RO System → Second-Level Purified Water Tank → Purified Water Pump (with ozone sterilization system) → Ultraviolet Sterilization → 0.22μm Microfiltration → Purified Water Use Point

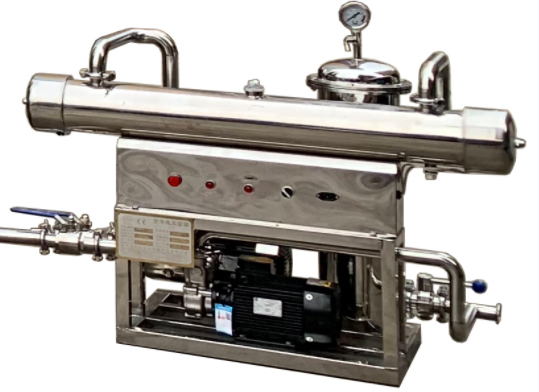

UV Ultraviolet Sterilization Principle and Application: In 1903, Danish scientist Niels Finsen proposed modern phototherapy based on the principle of light sterilization and was awarded the Nobel Prize in Physiology or Medicine. In the past century, UV sterilization has played an important role in the prevention and treatment of acute infectious diseases in human beings, such as the "two insects" incident in North America in the 1990s, SARS in China in 2003, and MERS in the Middle East in 2012. Recently, due to the serious outbreak of the new coronavirus (2019-nCoV) in China, UV light has been recognized for its high efficacy in killing viruses, becoming an important means for controlling the spread of the epidemic and ensuring life safety.

UV Sterilization Principle: UV light is divided into A-band (315 to 400 nm), B-band (280 to 315 nm), C-band (200 to 280 nm), and vacuum UV (100-200 nm) according to its wavelength range. Generally, C-band UV light is used for sterilization. After being exposed to C-band UV light, the nucleic acid (RNA and DNA) in the microorganisms absorb the energy of UV photons, causing the base pairs to polymerize and prevent protein synthesis, which makes the microorganisms unable to reproduce, thus achieving the purpose of sterilization.

Advantages of UV Sterilization:

1) UV sterilization produces no residual agents or toxic by-products, avoiding secondary pollution to the environment and oxidation or corrosion of the objects being sterilized.

2) UV sterilization equipment is easy to install and maintain, has reliable operation, and is low-cost. Traditional chemical sterilizers such as chlorine, chlorine dioxide, ozone, and peracetic acid are highly toxic, flammable, explosive, or corrosive substances that require strict and special sterilization requirements for production, transportation, storage, and use.

3) UV sterilization is broad-spectrum and highly efficient, able to kill most pathogenic organisms including protozoa, bacteria, viruses, etc. The radiation dose of 40 mJ/cm2 (usually achievable when low-pressure mercury lamps are irradiated at a distance of one meter for one minute) can kill 99.99% of pathogenic microorganisms.

UV sterilization has a broad-spectrum and highly efficient bactericidal effect on most pathogenic microorganisms, including the new coronavirus (2019-nCoV). Compared with traditional chemical sterilizers, UV sterilization has the advantages of no secondary pollution, reliable operation, and high efficiency in killing microorganisms, which can be of great value in controlling the epidemic.