ro water sterile plant with water heater tank

| NO. | Description | Data | |

| 1 | Salt rejection rate | 98.5% | |

| 2 | Working pressure | 0.6-2.0Mpa | |

| 3 | Voltage | 200v/50Hz,380V/50Hz etc. customized | |

| 4 | Material | Ss,CPVC,FRP,PVC | |

| 5 | Raw water (sea water) | TDS | <35000PPM |

| Temperature | 15℃-45℃ | ||

| Recovery Rate | 55℃ | ||

| 6 | Water-out conductivity(us/cm) | 3-8 | |

| 7 | Reverse Osmosis (RO) membrane | 8040/4040 | |

| 8 | Inlet Water SDI | <5 | |

| 9 | Inlet Water PH | 3-10 | |

|

Product characteristic |

|||||||

| Item | Capacity(T/H) | Power(KW) | Recovery(%) | One stage water conductivity(μs/cm) | Two Stage water conductivity (μs/cm) | EDI Water conductivity (μs/cm) | Raw water conductivity (μs/cm) |

| HDN-500 | 0.5 | 0.85 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-1000 | 1.0 | 2.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-2000 | 2.0 | 2.2 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-3000 | 3.0 | 3.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-5000 | 5.0 | 5.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-6000 | 6.0 | 6.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-10000 | 10.0 | 10.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| HDN-20000 | 20.0 | 20.0 | 55-75 | <10 | <5 | <0.5 | <300 |

| Components and functions | ||

| NO. | Name | Application |

| 1 | Raw water Tank | Store water,buffering pressure,overcome instability of supplying water by pipe,Ensure to supply water stable and continuously for whole system,normally customer provided |

| 2 | Raw water Pump | Provide needed pressure for every pretreatment filter |

| 3 | Mechanical filter | We use fiber glass or stainless steel vessel as housing, fill quartz sand,it can filter big particles impurities, Suspended substances, colloids etc. |

| 4 |

Activated carbon filter |

We use fiber glass or stainless steel vessel as Housing, fill activated carbon, remove color, odor, residual chlorine and organics substances. |

| 5 | Water softener | Adopt cation resin to soften water, cation resin will absorb Ca2+, Mg2+(Main elements for composing scale) |

| 6 | Security filter or pp filter | Prevent large particles, bacteria,viruses into RO membrane, Accuracy is 5 μs |

| 7 | High Pressure Pump | adopt two stage high pressure pump. Provide needed working pressure for RO system,High pressure pump ensure production capacity of pure water.(CNP pump or custom other brand) |

| 8 | Reverse osmosis System | Adopt two stage reverse osmosis system.Can remove particlescolloids,organicRO(reverse osmosis)system impurities,heavy metal ions,bacteria,virus,heat source etc.harmful substances and 99% dissolved salts.(RO membranes USA Film tec); Output water conductivity≤2us/cm. |

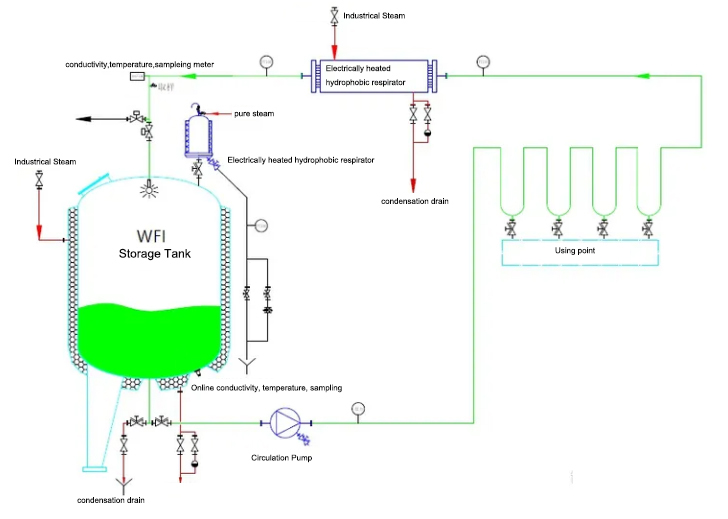

In order to ensure the safety and purity of water for injection, the water for injection system needs to be effectively sterilized. The following are common sterilization methods for water for injection systems:

Ultraviolet sterilization: Use a special ultraviolet sterilizer to irradiate water with ultraviolet rays to kill bacteria, viruses and other microorganisms in the water in a short period of time. This is a commonly used sterilization method without chemical residue.

Sterile filtration: Use a precision filter above 0.2 micron in the water for injection system for sterilization filtration. This filter helps remove microorganisms and particulates and prevents them from entering the water for injection.

Chemical Disinfection: Use appropriate chemical disinfectants to sterilize the water for injection system. Commonly used disinfectants include chloride, hydrogen peroxide and ozone. When using chemical disinfectants, you need to ensure the correct concentration and contact time to ensure effective killing of microorganisms in the water.

Temperature treatment: By using high temperature treatment water for injection system, bacteria and other microorganisms can be effectively killed. Common temperature treatment methods include heat sterilization and high-temperature steam sterilization.

Thermal sterilization is a commonly used sterilization method for water for injection systems, which uses high temperature treatment to kill microorganisms in the water. Common heat sterilization methods include the following two:

①Hot water sterilization: heating water to a certain temperature, usually above 80°C, for a certain period of time to effectively kill microorganisms in the water. This method is suitable for smaller-scale water for injection systems.

②High-temperature steam sterilization: Use steam for sterilization, heat water vapor to a certain temperature, and kill microorganisms in a high-temperature and high-pressure environment. This method is suitable for large-scale water for injection systems.

The advantage of thermal sterilization is that it does not require the use of chemical disinfectants during the sterilization process and avoids the problem of chemical residues. However, thermal sterilization requires corresponding equipment, and the operation process is relatively complicated. It is necessary to pay attention to the control of temperature and time to avoid adverse effects of heat on the equipment and water quality.

No matter which sterilization method is used, it is necessary to strictly abide by the relevant hygiene and disinfection regulations, ensure that the water for injection system is in a clean state, and regularly test the water quality to ensure the sterilization effect and water purity.