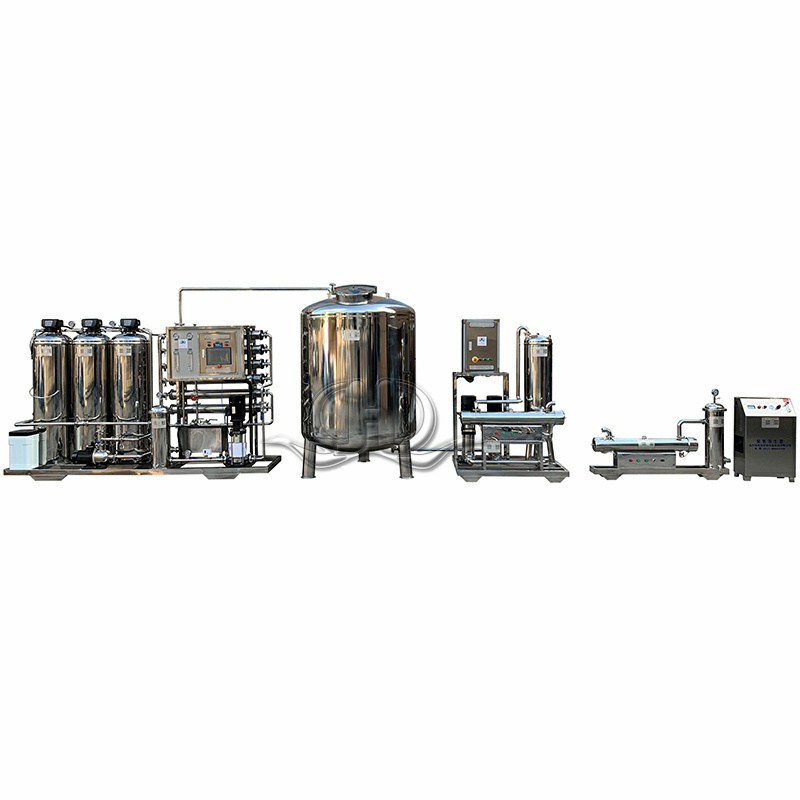

Small Reverse Osmosis system desalination unit uv sterilizer

Introduction and Maintenance Knowledge of Reverse Osmosis Pure Water Equipment

|

Product Detail |

|||||

|

1 |

Inlet water Type |

Well water/ underground water |

Outlet water Type |

Purified Water |

|

|

2 |

Inlet water TDS |

Below 2000ppm |

Desalination rate |

98%-99% |

|

|

3 |

Inlet Water Pressure |

0.2-04mpa |

Outlet water Usage |

Coating material production |

|

|

4 |

Inlet Membrane Water SDI |

≤5 |

Inlet Membrane Water COD |

≤3mg/L |

|

|

5 |

Inlet Water temperature |

2-45℃ |

Outlet capacity |

500-100000 litre per hour |

|

|

Technical Parameters |

|||||

|

1 |

Raw Water Pump |

0.75KW |

SS304 |

||

|

2 |

Pre-treatment part |

Runxin automatic valve/ stainless steel 304 Tank |

SS304 |

||

|

3 |

High pressure Pump |

2.2KW |

SS304 |

||

|

4 |

RO Membrane |

Membrane 0.0001micron pore size desalination rate 99%,recovery rate 50%-60% |

Polyamide |

||

|

5 |

Electrical control system |

Air switch,electrical relay, alternating current contactor switch,control box |

|||

|

6 |

Frame and Pipe Line |

SS304 and DN25 |

|||

|

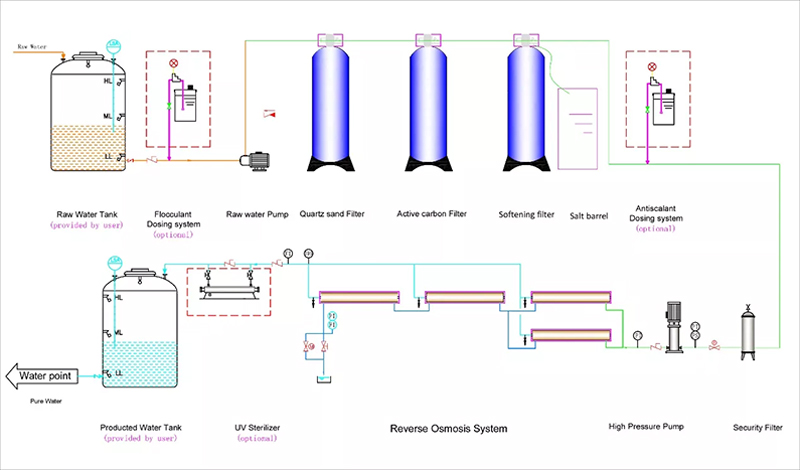

Function Parts |

|||||

|

NO |

Name |

Description |

Purifying Accuracy |

||

|

1 |

Quartz Sand Filter |

reducing turbidity, suspended matter, organic matter,colloid etc. |

100um |

||

|

2 |

Activated carbon filter |

remove the color,free chlorine, organic matter, harmful matter etc. |

100um |

||

|

3 |

Cation softener |

reducing water total hardness, make water soft and tasty |

100um |

||

|

4 |

Pp filter cartridge |

prevent large particles, bacteria,viruses into ro membranes ,remove particles, colloids,organic impurities, heavy metal ions |

5 Micron |

||

|

5 |

Reverse osmosis membrane |

bacteria, virus, heat source etc.harmful substance and 99% dissolved salts. |

0.0001um |

||

Processing: Feed water Tank→feed water pump→quartz sand filter→active carbon filter→softener→security filter→High pressure Pump→reverse osmosis system→pure water Tank

Precautions for using UV ultraviolet processors:

UV ultraviolet processor is a physical process and is one of the technologies widely used in sewage treatment. UV rays have bactericidal effects, and with the rapid development of technology, the share of UV ultraviolet processors in the field of water treatment has also been greatly improved.

The following are the precautions to be taken when using UV ultraviolet processors:

(1) UV rays should not be directly irradiated on human skin.

(2) UV rays have certain requirements on the temperature and humidity of the working environment: the irradiation intensity is relatively stable at above 20℃; the irradiation intensity increases with temperature between 5-20℃; the irradiation ability is stronger when the relative humidity is below 60%, and the sensitivity of microorganisms to UV rays decreases when the humidity increases to 70%; the sterilization power decreases by 30%-40% when the humidity increases to 90%.

(3) When sterilizing water, the water layer thickness should be less than 2cm, and the dosage of irradiation absorbed by water passing by should be more than 90000UW.S/cm2 to make the water effectively sterilized.

(4) When there is dust and oil stains on the surface of the lamp tube and sleeve, it will hinder the penetration of UV rays, so alcohol, acetone, or ammonia should be used to wipe it frequently (generally once every two weeks).

(5) When the lamp tube is started, it needs to be heated to a stable state, which takes a few minutes, and the terminal voltage is relatively high. After the processor is turned off, if it is immediately restarted, it is often difficult to start and it is easy to damage the lamp tube and reduce its service life; therefore, it is generally not advisable to start frequently.