stainless steel filter water treatment machinery

Introduction and Maintenance Knowledge of Reverse Osmosis Pure Water Equipment

|

Product Detail |

|||||

|

1 |

Inlet water Type |

Well water/ underground water |

Outlet water Type |

Purified Water |

|

|

2 |

Inlet water TDS |

Below 2000ppm |

Desalination rate |

98%-99% |

|

|

3 |

Inlet Water Pressure |

0.2-04mpa |

Outlet water Usage |

Coating material production |

|

|

4 |

Inlet Membrane Water SDI |

≤5 |

Inlet Membrane Water COD |

≤3mg/L |

|

|

5 |

Inlet Water temperature |

2-45℃ |

Outlet capacity |

500-100000 litre per hour |

|

|

Technical Parameters |

|||||

|

1 |

Raw Water Pump |

0.75KW |

SS304 |

||

|

2 |

Pre-treatment part |

Runxin automatic valve/ stainless steel FRP Tank |

FRP |

||

|

3 |

High pressure Pump |

2.2KW |

SS304 |

||

|

4 |

RO Membrane |

Membrane 0.0001micron pore size desalination rate 99%, recovery rate 50%-60% |

Polyamide |

||

|

5 |

Electrical control system |

Air switch, electrical relay, alternating current contactor switch, control box |

|||

|

6 |

Frame and Pipe Line |

SS304 and DN25 |

|||

|

Function Parts |

|||||

|

NO |

Name |

Description |

Purifying Accuracy |

||

|

1 |

Quartz Sand Filter |

reducing turbidity, suspended matter, organic matter, colloid etc. |

100um |

||

|

2 |

Activated carbon filter |

remove the color,free chlorine, organic matter, harmful matter etc. |

100um |

||

|

3 |

Cation softener |

reducing water total hardness, make water soft and tasty |

100um |

||

|

4 |

Pp filter cartridge |

prevent large particles, bacteria, viruses into ro membranes, remove particles, colloids, organic impurities, heavy metal ions |

5 Micron |

||

|

5 |

Reverse osmosis membrane |

bacteria, virus, heat source etc. harmful substance and 99% dissolved salts. |

0.0001um |

||

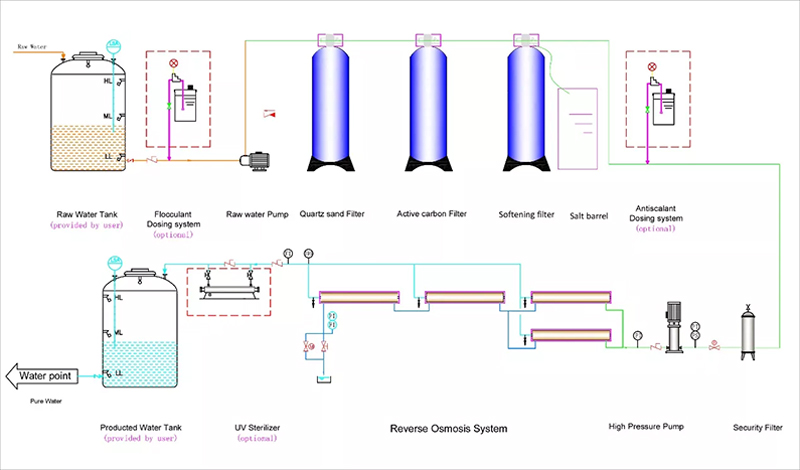

Processing: Feed water Tank→feed water pump→quartz sand filter→active carbon filter→softener→security filter→High pressure Pump→reverse osmosis system→pure water Tank

The main differences between a Fiber Reinforced Plastic (FRP) tank and a stainless steel tank are as follows:

Material: FRP tanks are made from a combination of fiber reinforcement (typically fiberglass) and a polymer matrix, while stainless steel tanks are made entirely of stainless steel. FRP tanks have excellent corrosion resistance and mechanical strength due to the combination of fibers and the polymer matrix. Stainless steel tanks have outstanding corrosion resistance and can withstand high temperatures.

Construction: FRP tanks are manufactured using a lamination process, where layers of fiber reinforcement and resin are laid down to create the tank structure. Stainless steel tanks are typically fabricated as a single-piece structure without the need for lamination, making them more robust and durable.

Characteristics: FRP tanks are light in weight, corrosion-resistant, non-contaminating, insulating, and have good impact resistance. They can be manufactured in various shapes and sizes according to specific requirements. Stainless steel tanks are known for their excellent corrosion resistance and are widely used to store various chemicals, liquids, and gases. They have a smooth surface, making them easy to clean, and they have a longer service life.

In summary, FRP tanks and stainless steel tanks differ in terms of material, construction, and characteristics. The choice of storage tank depends on specific application requirements and considerations.